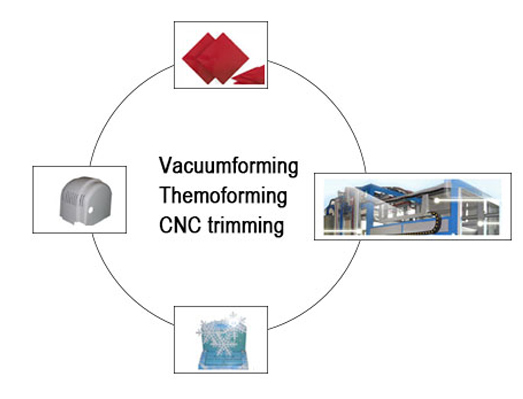

Vacuum forming is a very economical method for producing plastic parts. This process can produce large or small parts in low quantities at a reasonable price. This involves the controlled heating of a thermoplastic material to a temperature where it is pliable enough to be altered by the shape of a mold. This mold can be made of wood, phenolic or aluminum, so tooling can be optimized depending on the properties required. In this method, the heated thermoplastic is forced against the mold by the air pressure differential created by pulling a vacuum between the sheet and the mold.

professionally engaged in the research and manufacture of vacuum formed plastic products including post-processing. We have abundant experienced and skillful engineer and technician. Have been a leading company in this industry. The maximum size of product can reach is 3000*2000*800mm(length*width*high), and the thickness could reach10 mm.

We are not just only provide simple process for plastic parts, we make use of all kinds of software, like: CAD, PRO-E, SOLIDWORKS etc to handle with customers’ drawing and meet their requirement, also we make design ourselves according to customers’ idea.

-Mr. Kevin worked at Rongzhong as Sales Manager since 2009, excellent communication skills,

professional vacuum forming/thermoforming process knowlegde, could provide good solutions for plastic projects.

hope we could help.

E-mail: kevin@zhenrong.com.cn